Effective display of FMCG products without a planogram?

If you are an FMCG manufacturer, then you surely notice the correlation between sales and in-store product visibility. Likewise, you...

If you are an FMCG manufacturer, then you surely notice the correlation between sales and in-store product visibility. Likewise, you are no stranger to the challenge of effective communication of guidelines and KPIs to persons directly responsible for executing the strategy. They are usually the company’s own representatives or employees of an outsourcing agency. Sometimes, you can suggest your own vision of product arrangement on shelves to a particular store or retail chain.

- Merchandising standards are a set of rules that should be followed by representatives who take care of store display.

- In the retail industry, planograms are used to visualize product display standards.

- However, the reality in stores is much more sophisticated than a schematic planogram, and standards can be fulfilled in many different ways.

- eLeader Shelf Recognition AI is a tool that examines the alignment of products against rules (standards), and not planograms as therefore it provides results that are much more useful for business than a 0/1 compliance test with a drawing.

- Working with the tool requires the representative only to take photos of displays in stores, the rest of the audit process is performed by artificial intelligence.

What is the standard?

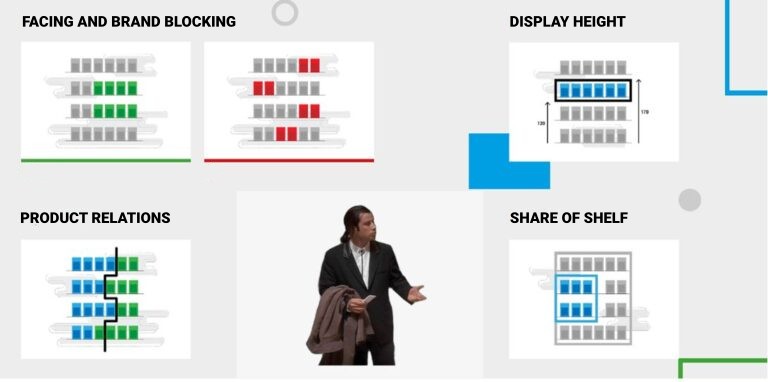

Companies have different interpretations of standards and therefore different approaches to creating and enforcing them. Some merely care about the availability of the products specified in the inventory list. Those more ambitious ones examine product shortages, the number of faces of each SKU, and measure the share of shelf. “Heavyweight players” go as far as to develop advanced perfect store strategies which determine the location of categories and products, share in the golden zone and vicinity of specific products. There are also such KPIs here as arranging the right order of flavours, creating product blocks, specific proportions within categories, and even the right representation of volume and label variants.

The very defining of visual merchandising objectives requires a vast amount of knowledge and understanding of the industry and the market. But this is not all. To implement a standard, you still need to convert shelf measurements into real numbers, assign the right importance to the indicators, set objectives for those in charge, and eventually ensure that the knowledge is acquired through training and periodic testing.

Display strategy

The above-mentioned set of display management principles would not be complete without the correct execution of all standards and inspection procedures following a representative’s visit. But there is even more to this. The assumptions regarding the indicators need to be constantly (or at least periodically) monitored and adjusted to the store segment, implementation potential, number of field force, changing market situation, seasonality, changes to the product portfolio, as well as conditions of agreements with retail chains.

Believe it or not, there are even more factors that have to be taken care of if you want to effectively execute your display strategy (after all, you need to manage the responsibilities of representatives and auditors, plan visit schedules of a certain length and appoint remote teams to perform random inspections of photos documenting the compliance of shelf arrangement with the standard).

Finally, it is a good idea to compile the display data with transaction and production data and analyze it all in a reliable BI system. This much, indeed.

Planograms

Companies committed to display standards have established a practice of creating planograms. They are the ultimate results of the work of category managers who use vast areas of knowledge about products, consumer psychology, space planning, etc.

When designing a planogram, i.e. a display pattern that will generate the best sales opportunity, products are drawn on shelves as templates or placed in Excel tables which contain information on specific SKUs, their quantity and location on shelves.

Obviously each store, or at least a segment of stores, requires its own planogram.

Planograms need to be changed when the company’s new products or ones of competitors appear in stores or when KPI standards change.

Read also:

- Energy drinks 2024: industry view through the lens of AI

- How to maintain merchandising standards and a perfect store thanks to AI [VIDEO]

- Price on shelf different from price at checkout – what should the shop do?

- How to implement Shelf Recognition tool, organize the processes and win the market?

Back on earth

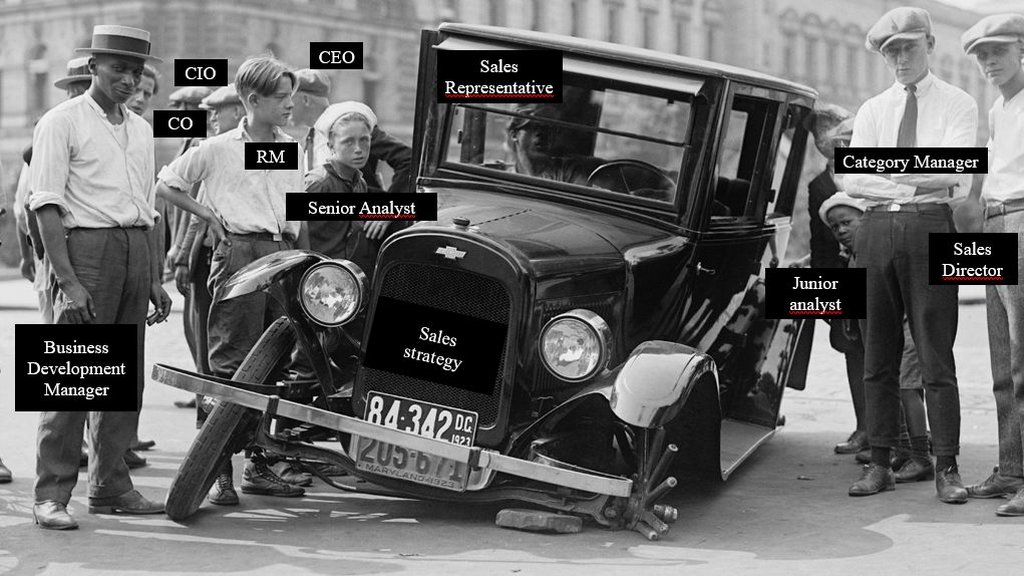

Now, consider the situation of the field workers who carry the burden of executing the strategies painstakingly developed by ambitious category and sales managers.

Limited by time, a representative has to perform a number of tasks during a visit to the shop (orders, surveys, delivery checks, handling deliveries, completing store info, etc.)

It is also at this time that he or she is supposed to check whether the shelf is arranged in accordance with the guidelines, so the representative glances at the planogram and… scratches their head.

The store reality usually differs from what is on paper: the layout of competitors’ products does not reflect that in the planogram, as they take a different part of the shelf. On the contrary, our products are not displayed the way our CM department expects it, but in line with the particular shop’s customers’ preferences. The store personnel stack our products in the golden zone, mistaking shelf 4 for shelf 5. Product blocks are arranged vertically instead of being displayed along the entire length of the shelf.

To make matters worse, although our products seem to look attractive in an arrangement that meets most of the standards, the rigid planogram is unforgiving: NO COMPLIANCE!

An inflexible planogram, being just one of many possible visual representations of standards, does not only cause the representative’s frustration that it is impossible to fulfill. It also prevents figuring out the best way to adjust execution in the field to the guidelines.

Comparing with a picture is a relatively simple and mechanical job – thinking about standards offers more flexibility. But it requires more time and longer training.

What if there was a way to execute more effectively?

Well, there already is one and we happen to be its authors. It is called eLeader Shelf Recognition AI and it consists in automated display analysis by AI against predefined standards (KPI) of shelves (algorithms, not pictures) and providing the results of the audit in real-time, during a representative’s visit.

To put it simply.

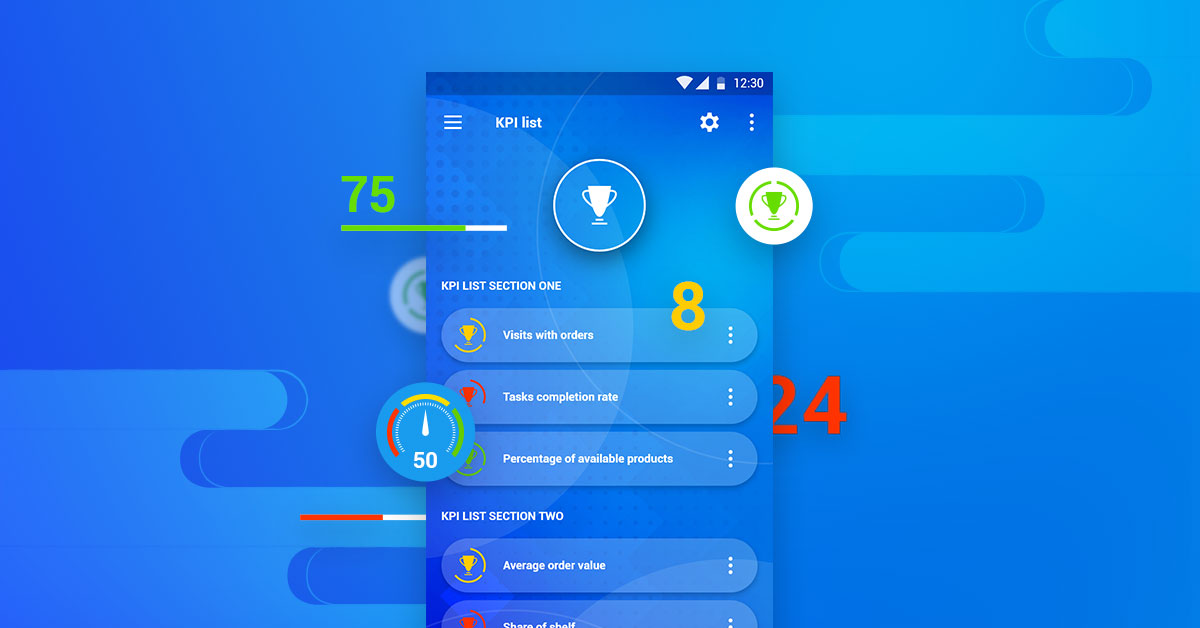

With eLeader Shelf Recognition AI, a representative takes photos of products with a smartphone and a moment later receives a message on the same device about how well the standards are met and what needs to be improved to obtain perfect store, a bonus, the manager’s handshake or a cinema ticket.

Even simpler? – maybe a picture will help:

To put it brief: no more staring at the planogram in the store or tedious verification of photos in front of the office monitor. eLeader Shelf Recognition AI utilizes the power of neural networks and processors of artificial intelligence which recognizes products and calculates the necessary guidelines for them. Simultaneously, it saves the time and energy of the representatives, who can focus more on arranging products on the shelf and, more importantly, carry out their sales-related duties and perform more visits in a single working day.

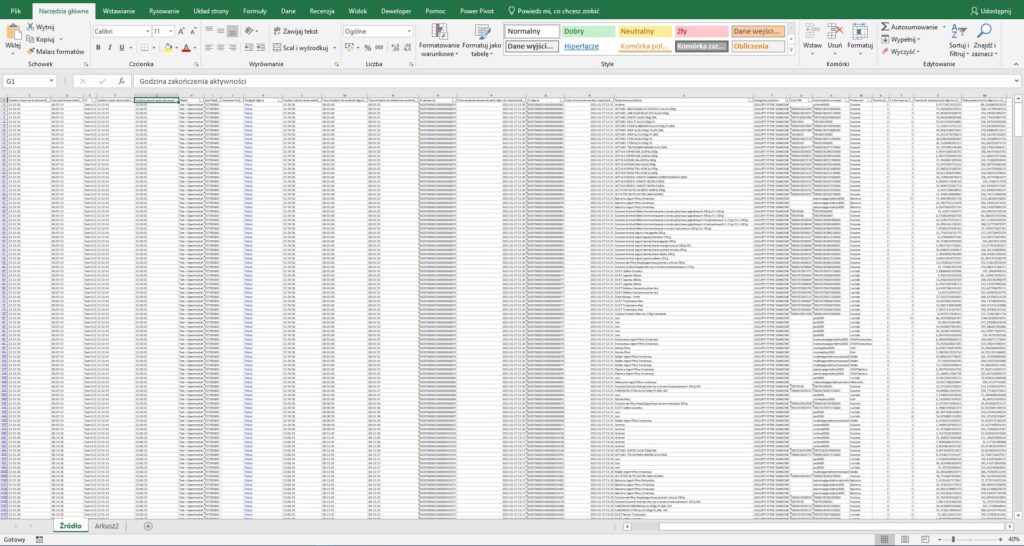

There is a vast amount of data coming from such a survey:

… but this is how we cope with it:

An intelligent plan for better merchandising

The good news is eLeader Shelf Recognition AI is not magic but sheer science and technology. The solution is available for all manufacturers offering products offered in distinguishable packaging – visible to customers.

If you want to partake in a technological revolution – just us our clients do, do not hesitate to join us. Not only will we explain everything to you step by step, but we will also think together about how to harness a technological warhorse to the chariot of your sales strategy, so you can proudly ride it towards the setting sun.

Email us today or download our ebook to learn how eLeader Shelf Recognition AI works.

By the way, if you love planograms and you are seeking to automatically verify the compliance of the display with the existing planogram, eLeader Shelf Recognition can deliver a solution right onto your smartphone.